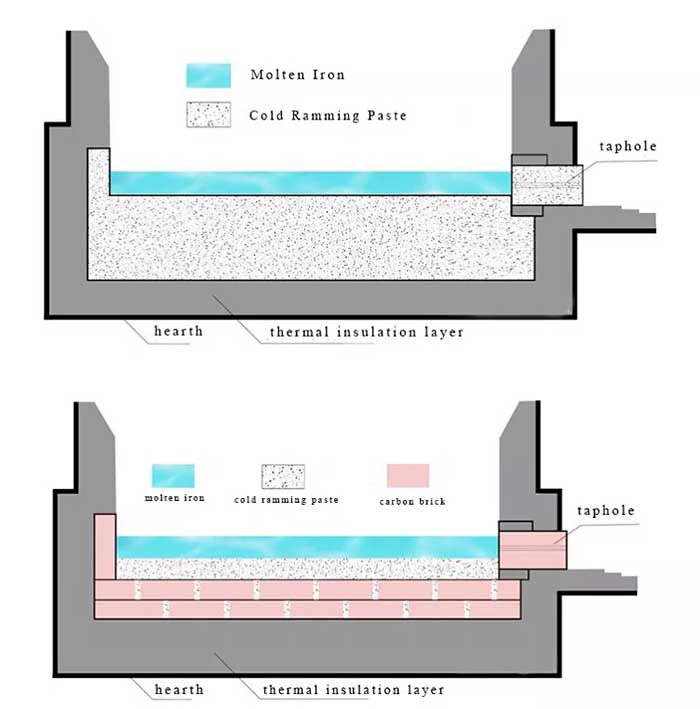

Cold ramming paste is a carbon material used for masonry, widely used in aluminum electrolysis cell, blast furnace, smelting furnace, calcium carbide furnace, and other industrial furnaces, filling the gap between charcoal and cooling equipment, charcoal and charcoal, charcoal, and firebrick.

Cold ramming paste is made from high-temperature electrical calcite anthracite coal, artificial graphite, and natural graphite. Coal tar pitch, coal tar, and anthracite oil mixed oil additives as a binder, through the broken, ingredients, stirring and kneading for construction at ambient temperature.

Through a global team of specialists, we offer technical support to our customers: Rongxing Group assists with electrode audits and training seminars for in-depth understanding of your electrode processes.

Cold ramming paste is widely used in industrial kilns such as aluminum reduction cells, iron-making blast furnaces, smelting furnaces, calcium carbide furnaces.

Do not squeeze during loading and transportation to avoid tamping in advance.

Storage conditions require normal temperature, avoid light & wind.

The storage time of cold paste should not be too long, and the shelf life is generally within one year, to avoid the paste from drying out due to the evaporation of the binder. The use of expired or dry cold ramming paste may cause delamination and uneven quality during construction, increasing the risk of leaking during roasting and operation.

| Property | Unit | Mean value | |

| Volatile Matter | % | <24.0 | |

| Ash | % | <8 | |

| Bulk density | Green mix | g/cm3 | >1.7 |

| Baked mix | >1.55 | ||

| Open porosity | Green paste | % | <5 |

| Baked paste | <18 | ||

| Thermal Conductivity@30ºC | Green paste | W/mK | <6 |

| Baked paste | <8 | ||

| Granularity | mm | <8mm | |

| Max Operaturing Temp. | ºC | 1800 | |

Our cold ramming paste can be constructed in the normal temperature range of 17-42 °C. There is no asphalt smoke during construction, which improves the working environment of the construction personnel; Rongxing cold ramming paste is designed according to international standards, with good thermal shock resistance and the roasting shrinkage rate is less than 0.15% with good tamping, and with no delamination.

Fill the form get in touch with us and get latest quotation regular. Or send mail to: [email protected]

Unit 2, Building 1, No. 80 Puhui Road, Zhengzhou City, Henan Province, China

Mobile: +8619937179450

Email: [email protected]